- Kasarwadi, Pune

Call Us : +91 84466 13200 / 600

SCADA (supervisory control and data acquisition) Automation Training Services, Institute, Courses

Our institute is situated in Kasarwadi, Pune, Maharashtra, India

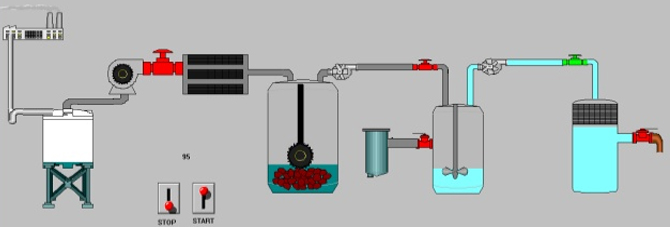

Acronym for supervisory control and data acquisition, a computer system for gathering and analyzing real time data. SCADA systems are used to monitor and control a plant or equipment in industries such as telecommunications, water and waste control, energy, oil and gas refining and transportation.

Programmable Logic Controller or PLC is a computing system used to control electromechanical processes. SCADA stands for Supervisory Control and Data Acquisition. It is a type of industrial control system that is used to monitor and control facilities and infrastructure in industries.

A more specific use of the term is for a Supervisory Control and Data Acquisition system or SCADA, which refers to a specific class of system for use in process control, often on fairly small and remote applications such as a pipeline transport, water distribution, or wastewater utility system station.

SCADA systems deploy multiple software and hardware elements that allow industrial organizations to: Monitor, gather, and process data. Interact with and control machines and devices such as valves, pumps, motors, and more, which are connected through HMI (human-machine interface) software

|

Siemens Wicc SCADA |

|

Introduction and Architecture of SCADA |

|

What is meant by PLC SCADA? |

|

Difference between HMI & SCADA |

|

Creating Screens |

|

Creating Tag database |

|

Create Analog/ Digital Alarm, BAR Graph, Historical trends |

|

Input & Output display |

|

Text Display & Numerical Display |

|

Scripting |

|

Real Time Clock |

|

Interface with PLC |

|

Small Project Base on SCADA |